Air Cargo Container Certification

Guaranteeing the airworthiness of our air cargo products

The importance of certified ULDs

Unit Load Devices (ULDs) are used to transport cargo of all shapes and sizes. But their value extends far beyond loading efficiency and consignment protection. ULDs are also essential to flight safety, whether they come as aircraft containers or as pallet/net combinations.

A ULD can only be loaded into an aircraft after its airworthiness has been proven. That is because it must be directly restrained by the aircraft’s Cargo Loading System. Proof of airworthiness comes in the form of EASA or FAA certification. If a ULD is not certified, it can’t be placed in the Cargo Loading System.

VRR is extremely experienced in getting standard and customised ULDs certified. Like always, we love to share some of this knowledge with you!

The benefits of certified ULDs

There are some very clear benefits to using certified containers vs. non-certified containers.

Getting certification: How does it work?

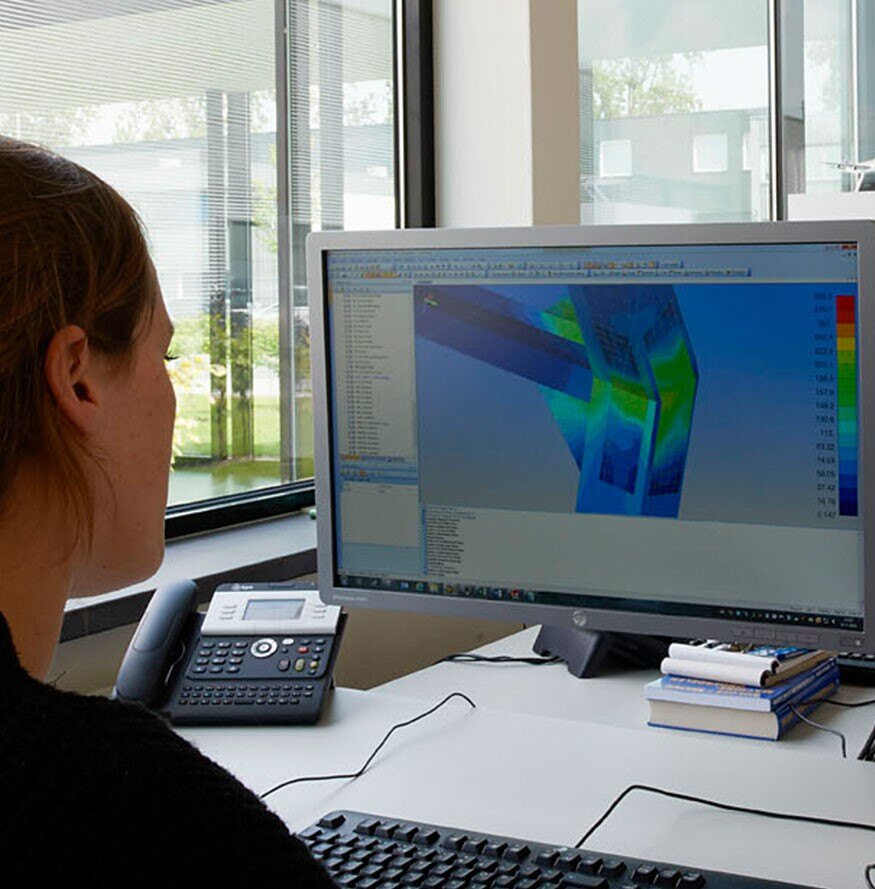

Our team of compliance engineers is dedicated to the certification of our ULDs. They are specialised in making sure every single ULD meets the right standard and is provided with the corresponding proof.

Aviation safety standards are set high for good reason. Manufacturers like VRR must prove conclusively—through testing and analysis—that a ULD can withstand a high load while restrained in an aircraft’s hold and in accordance with TSO and other standards.

Once our team has convinced EASA that the design, testing and manufacturing meets the approved standards, the ULD can be classed as certified.

The certification process

- Determine which requirements apply to the ULD's design

- Determine how we can achieve compliance with the requirements

- Evaluate the design to ensure that it complies with the requirements

- Ensure the design is not overengineered

- Submit calculations and test results to the regulatory authority

- Receive approval for use from the regulatory authority

How long does it take to get a ULD certified?

The time it takes to get a ULD certified depends on whether it’s a completely new design or a modification on an existing design. If we are just modifying the design, it may take us just a couple of days to run the compliance analyses.

The certification of a standard design that’s been customised usually takes us about a week of analysis, although it largely depends on the complexity of the customisation.

The most labour-intensive certification process is for new and innovative designs. These can take at least 200 hours of analysis, testing and documenting to make sure they are structurally sound.

The alphabet soup of ULD compliance

If you’re not a design or compliance engineer, it can get a little confusing when we start talking about TSOs, ETSOs and SAE standards, so here's a quick summary for you:

EASA

The European Union Aviation Safety Agency (EASA) is responsible for ensuring safety and environmental protection in air transport in Europe. Its role includes harmonising regulations and certification, developing the single EU aviation market, drawing up technical aviation rules, and certifying aircraft and components.

(E)TSO

A European Technical Standard Order, or (E)TSO, is a certification issued by EASA. It ensures that aircraft parts or components meet specific safety and performance standards across European aviation. ETSOs often have the same numbers as TSOs, which are issued by the FAA, and are broadly similar in content, but there can be minor technical differences. Note that (E)TSOs are not the only way to get approval for parts and appliances.

(E)TSOA

This stands for (E)TSO Authorisation, which is approval from FAA or EASA to manufacture a material, part, or appliance to a (E)TSO standard. If a company receives an (E)TSOA, it may design and produce the article, but it may not install or use it.

FAA

The Federal Aviation Administration (FAA) is an agency of the U.S. Department of Transportation. It is responsible for the safety of civil aviation. Its role includes regulating civil aviation, encouraging new aviation technology, and developing and operating a system of air traffic control and navigation for both civil and military aircraft.

FRC

A passive fire-resistant container (FRC) is a ULD whose panels and doors are typically made out of fire-resistant materials. It is designed to suppress fires through oxygen starvation and used on a voluntary basis to mitigate the risk of certain classes of fire.

TSO

Over a hundred TSOs have been issued over the decades, but only three relate directly to ULDs: TSO C90e: Cargo Pallets, Nets and Containers (Unit Load Devices); TSO C172: Cargo Restraint Strap Assemblies; and TSO C203: Fire Containment Covers.

TSOs for ULDs

The Federal Aviation Administration (FAA) is an agency of the U.S. Department of Transportation. It is responsible for the safety of civil aviation. Its role includes regulating civil aviation, encouraging new aviation technology, and developing and operating a system of air traffic control and navigation for both civil and military aircraft.

SAE

For many TSOs, the FAA establishes the technical requirements using an external standard. Most of those standards are created by SAE International, which has several committees made up of subject matter experts.

SAE AS8992

This is the design and testing standard for Fire-Resistant Containers (FRCs). It is now referred to in (E)TSO C90e.

ULD

A Unit Load Device (ULD) carries any type of cargo transported by plane. It can be a container or a pallet/net combination. It had four main purposes: protect the cargo, protect the plane, maximise cargo space, and facilitate handling during transportation. A certified ULD is designed to be directly restrained by the aircraft’s Cargo Loading System.

Articles on certification

Take a deep dive into the world of certification and read our blog articles.

3 Myths Debunked about Aviation: Certified vs. Non-Certified ULDs – Part 2

In the previous article about the myths surrounding the standards of certified...

How We Guarantee the Airworthiness of ULDs

When you order a Unit Load Device, you probably look for the safest and most...

How to Improve the Performance of Your ULD

ULDs are built to withstand extreme conditions. They have to be. They’re...

.png)