Maximising an aircraft’s cargo space

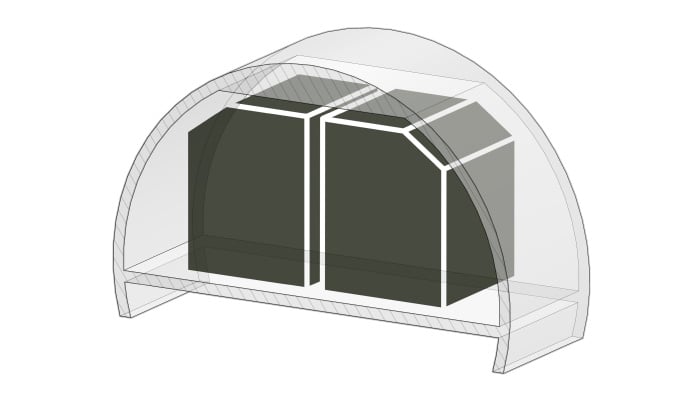

Explaining the difference between optimal fit, non-optimal fit and no fit.

When designing an Aircraft Unit Load Device (ULD), careful thought is given to making the most of the aircraft’s cargo space. Unfortunately, aircraft holds come in many shapes and sizes, which means that ULDs also have to come in many shapes and sizes.

Since ULDs are often transferred between different types of aircraft, this gives rise to three types of fit: optimal fit, non-optimal fit and no fit:

- Optimal fit: the ULD’s contour is the same as the aircraft’s hold;

- Non-optimal fit: the ULD’s contour does not exactly match the hold’s contour;

- No fit: the ULD does not fit the aircraft’s hold.

Clearly, a ULD that fits the contour of the hold maximises the aircraft’s cargo space. In addition, a ULD can be an optimal fit for one or more than one type of aircraft. That doesn’t mean this ULD can’t be used in another type of aircraft if it’s not an optimal fit. In fact, it may be compatible with several different aircraft. It simply won’t be making the most of every hold’s space.

How do you decide which is the most suitable contour?

The contour you select depends on a few factors:

- Which airline do you use?

- Which aircraft does the airline use?

- Is the ULD also going to be used for land/sea transport?

- What type of cargo is being transported?

- Do you need to use more than one aircraft or airline (interlining)?

To help you select the best contour for you, VRR has developed the ULD – Aircraft compatibility tool.

Know which ULD you need?

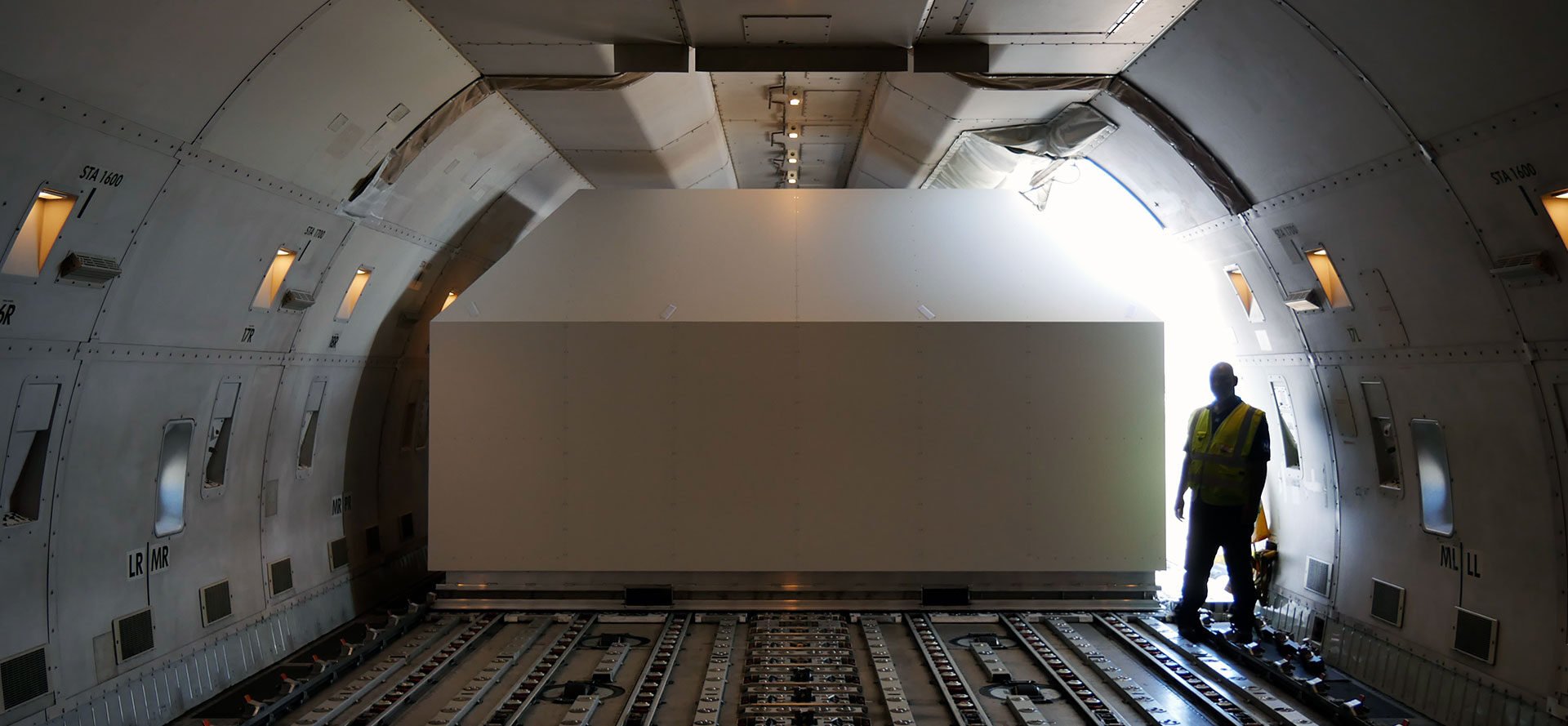

Then come and meet our General Cargo Containers. The shapes and sizes may be standardised; the build is definitely not. Each certified ULD is designed with operational efficiency and aircraft compatibility in mind, offering you quick and easy loading access, maximum internal cargo volume, effective cargo protection and excellent durability.

.png)