AKP Technical Support

Before using the AKP system make sure the correct personal protective equipments are used such as:

- Safety gloves

- Safety glasses

- Hearing protection

Further during operation of the AKP and it's subsystems:

- Do not eat

- Do not drink

- Do not smoke

Make sure you are always working safe and on a safe location

Please use the "back" button instead of the browser back button to go one page back.

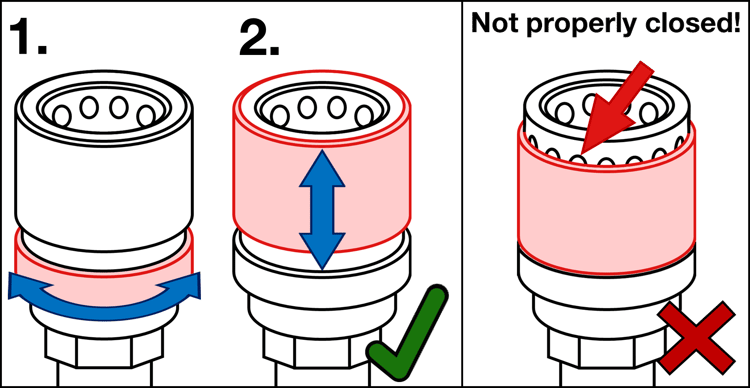

To attach/detach the hoses, follow these steps:

1. Unlock the lock ring by rotating it until it springs open.

2. Pull the connector part down while (dis-)connecting it from the container.

If the bearings are visible, the connector is not properly connected to the RZY/MZA.

The glycol hoses have a locking mechanism. See image below for more details.

Does this solve the problem?

Does this solve the problem?

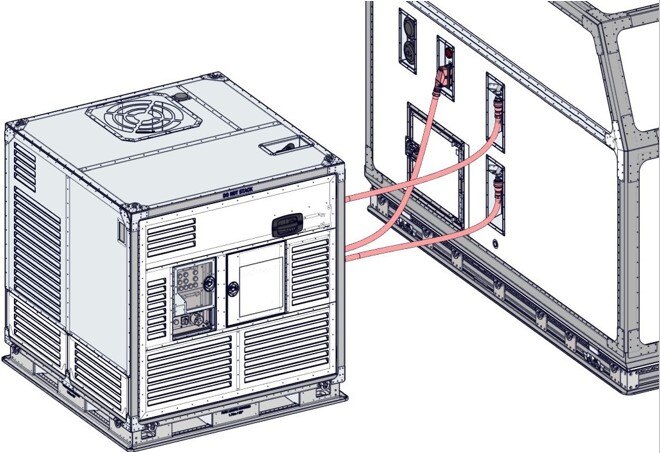

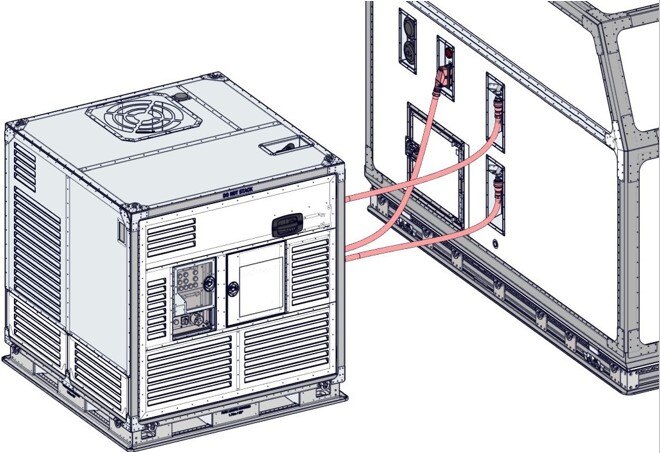

Are both cables from the Climate Control Unit connected to the generator?

1. Power cable (red)

2. Data cable (grey)

Does this solve the problem?

Connect the 2 cables according to the instruction in the OM and wait for 15 minutes. Does this solve the problem?

Check the temperature in the container. Is the temperature within spec?

Feel the hoses connected to the RZY/MZA. Is one of these statements true?

- If the temperature inside the container is too hot (above 23C°), the upper hose should feel cold

- If the temperature inside the container is too cold (bellow 19C°), the upper hose should feel warm

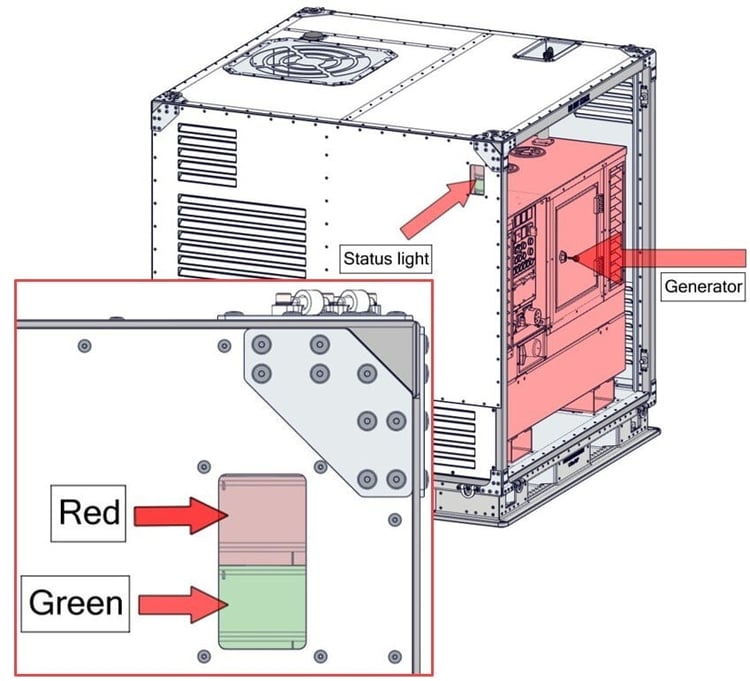

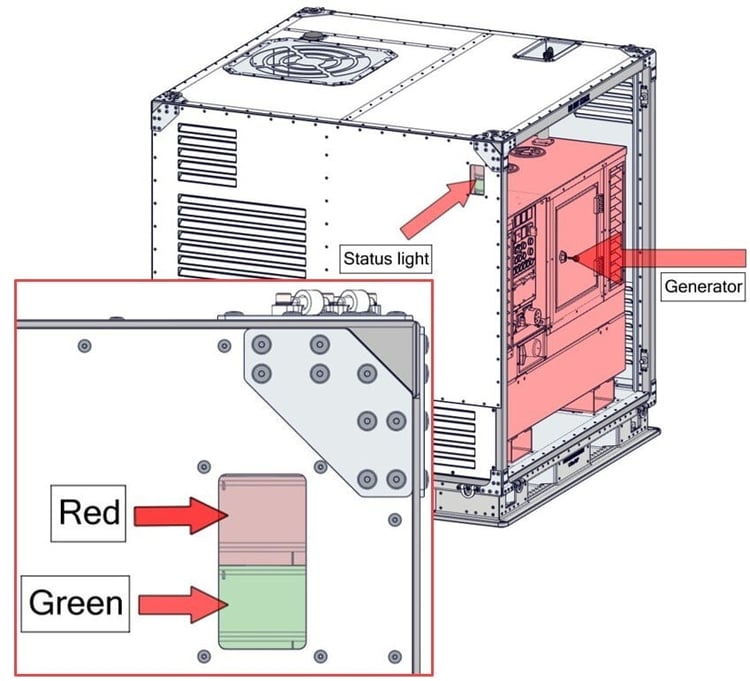

Does the AKP light turn green or is the temperature inside the container slowly changing towards 21C°?

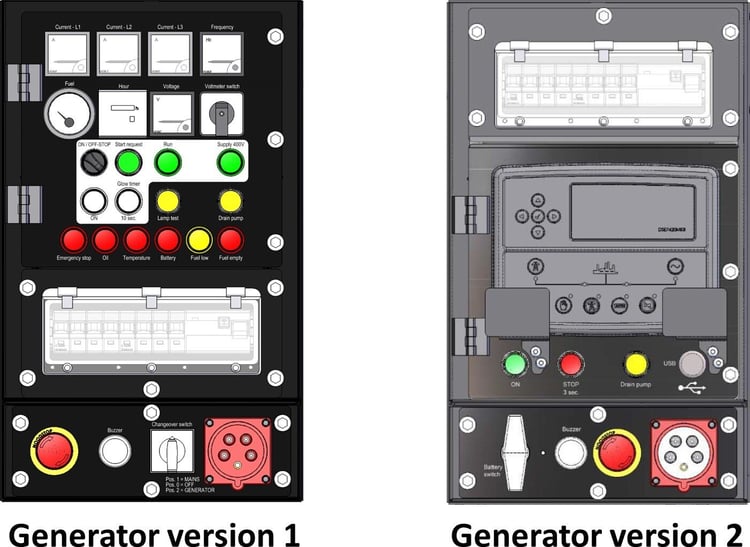

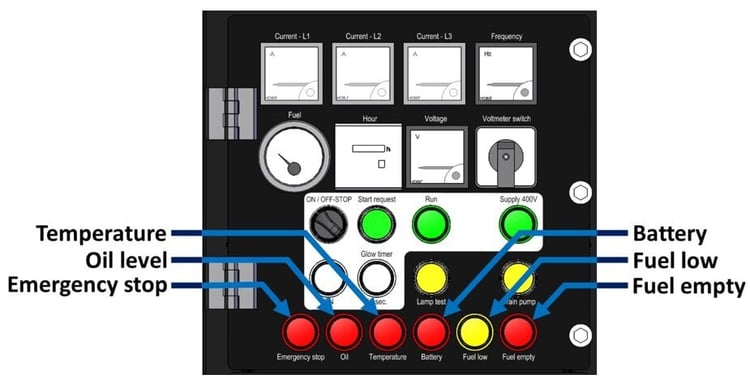

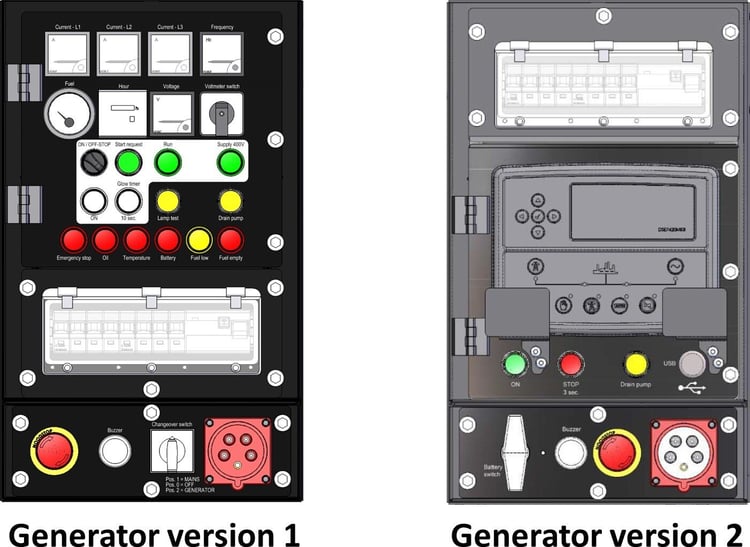

If only the Fuel low error is shown, the generator can still function.

If the Fuel empty error is shown, or if the fuel level reaches 10% or less, the generator may shut-down in order to prevent damage to the generator.

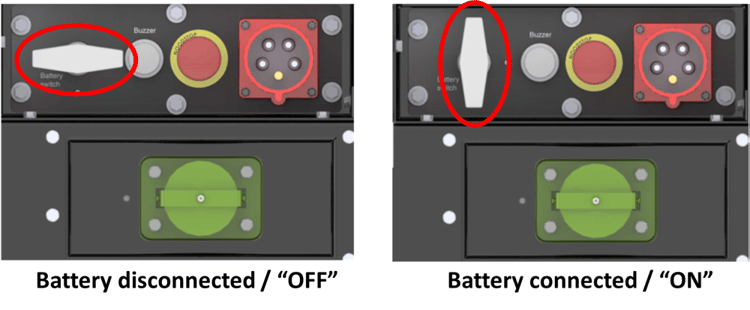

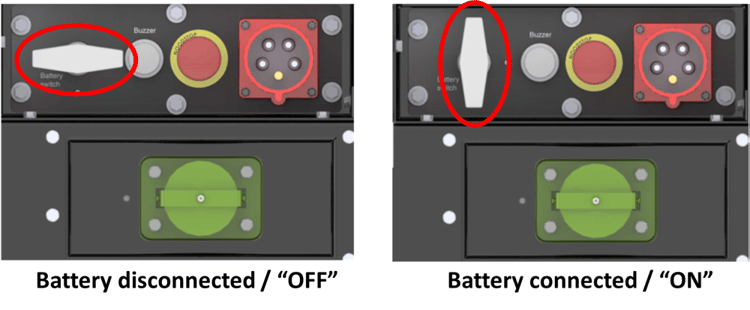

The battery is "ON" / connected if the switch is in vertical position.

Symptoms to look for include:

- Engine struggles to start

- The lights and/or display are dimmed

- There is a battery error on the control panel

- The generator won't start at all

Does this solve the problem?

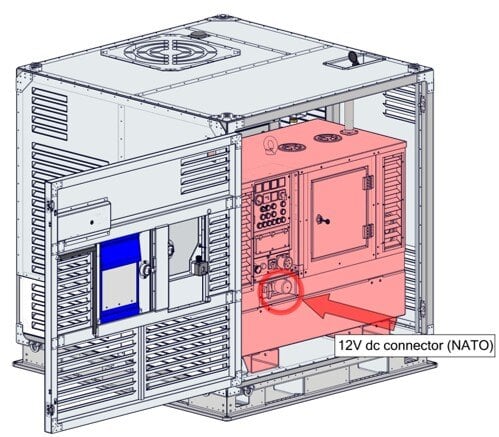

1. Check if there is a suitable external power source nearby (on the truck).

2. Check if there is a NATO cable available.

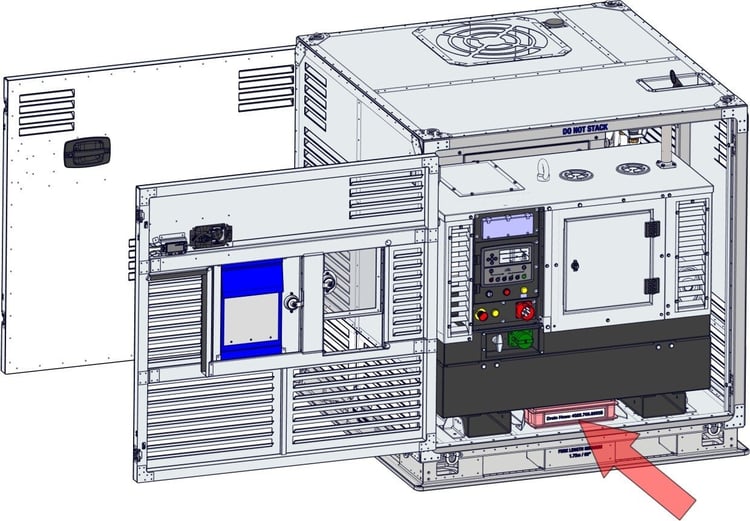

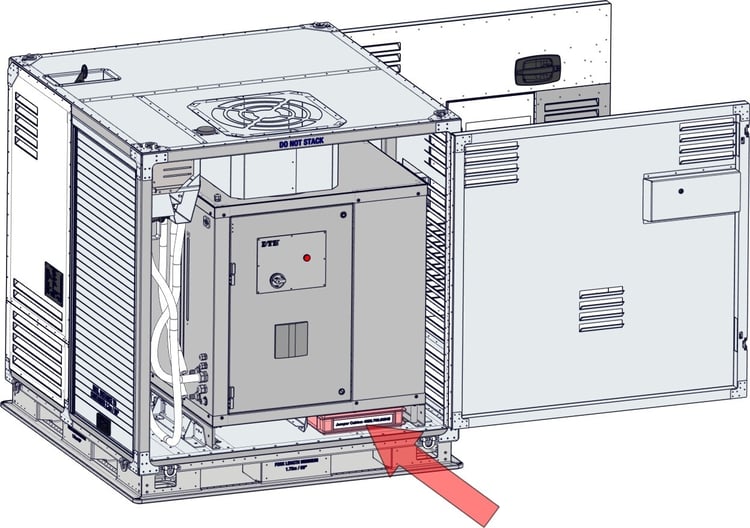

Some AKP's contain a NATO cable, which can be found underneath the generator or CCU. IMPORTANT: Only use the NATO cable! Only use 12V! Always consult the Operating Manual in when in doubt!

WARNING: Only use the NATO cable with 12V!

Connect the NATO cable to the source (red is positive, black is negative) and generator, start the generator and let it run for atleast 15 minutes. The NATO cable can be disconnected if the generator is running.

Does the generator now start?

Does this solve the issue?

Take note of the colour of the fluid. Do not touch the fluid!

Which device is leaking fluids?

Call the forwarder/supervisor and discuss how to proceed.

If no error or solution can be found, or if the error is unclear, consider calling E-Power. Make sure to have the product number of the generator available.

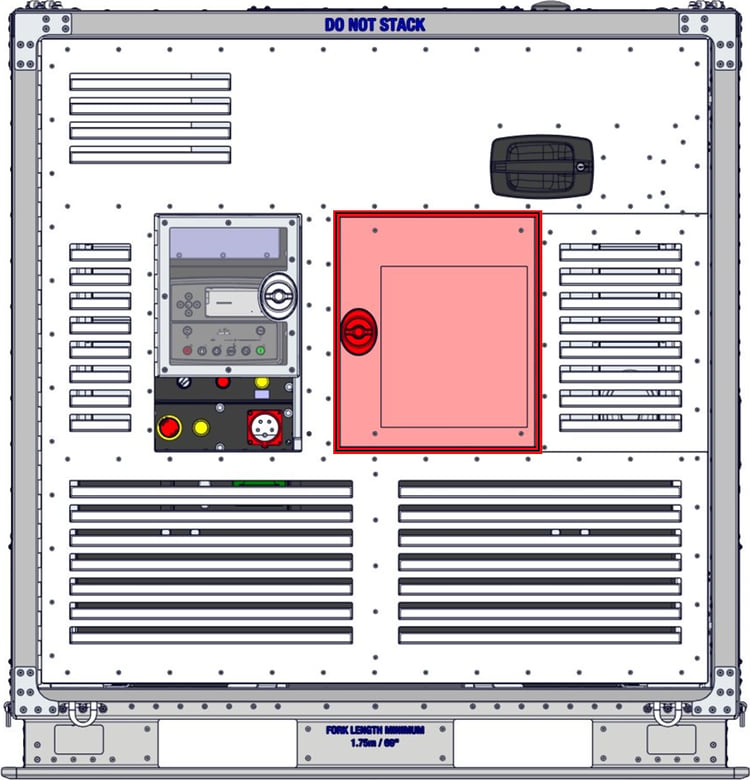

Ensure a minimum clearance of 600mm around the AKP to allow heat and exhaust gases to move away from the AKP. Make sure no ventilation panels are blocked or coverd.

Call the forwarder/supervisor and consider the following:

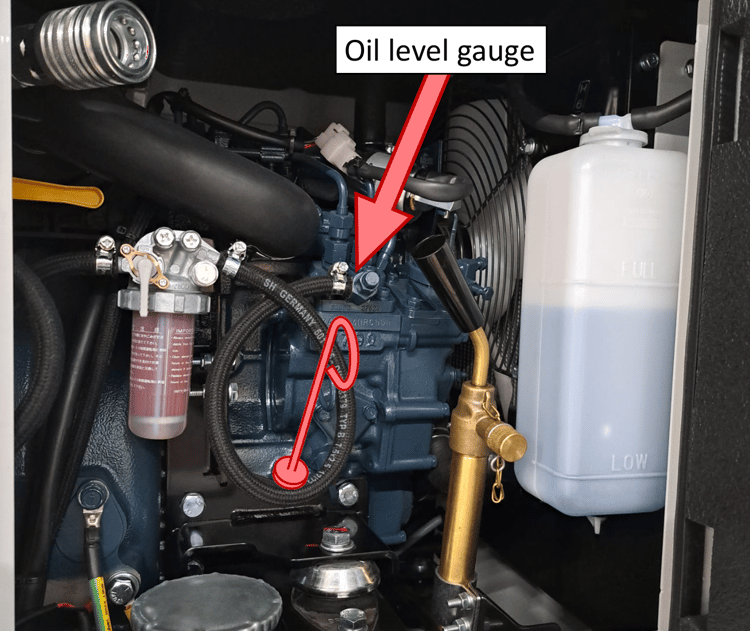

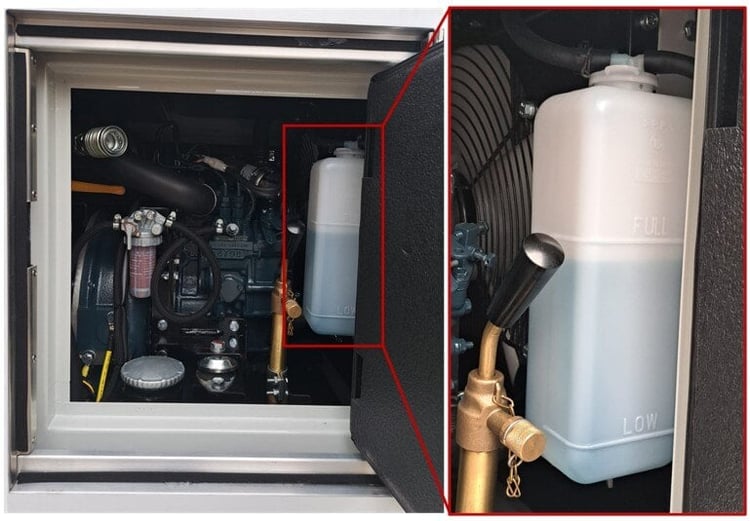

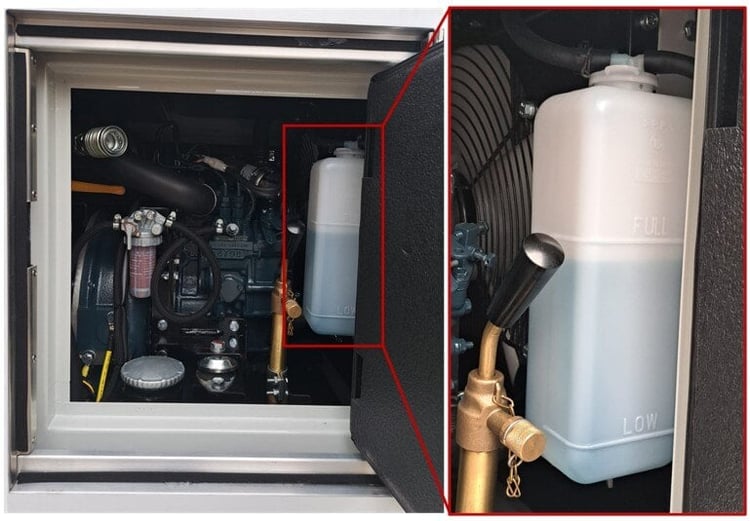

Check cooling fluid of the generator. Is the cooling fluid low (or empty)?

Does this fix the problem?

A tripped fuse can be recognised by a lowered fuse switch.

Are any of the fuses tripped?

Inform the forwarder or Superisor and discuss how to proceed.

Inform ASML.

After approval, you may reset the emergency switch by pulling out the emergency switch. Does this solve the issue?

Discuss how and when to refill the cooling fluid. Use the Operating Manual or generator manual for detailed instructions and specification of coolant.

In order to prevent damages, it is not allowed to start the generator with low/empty cooling fluid

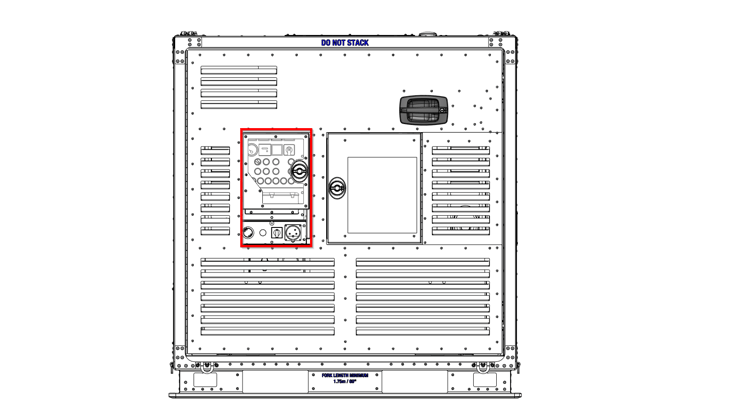

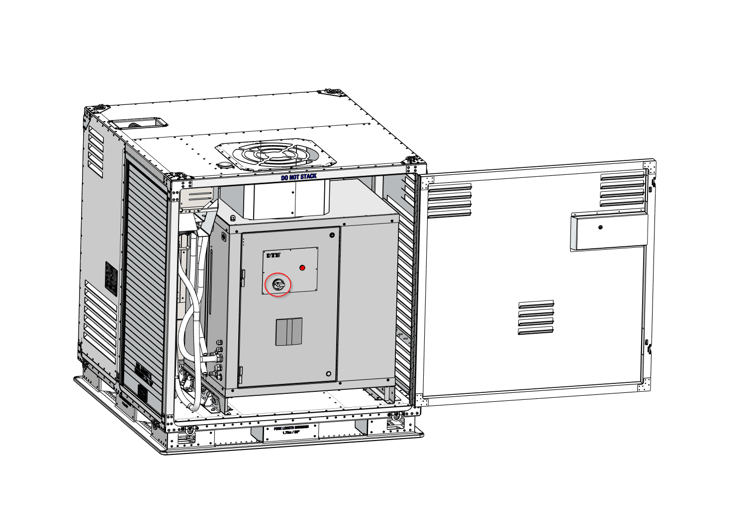

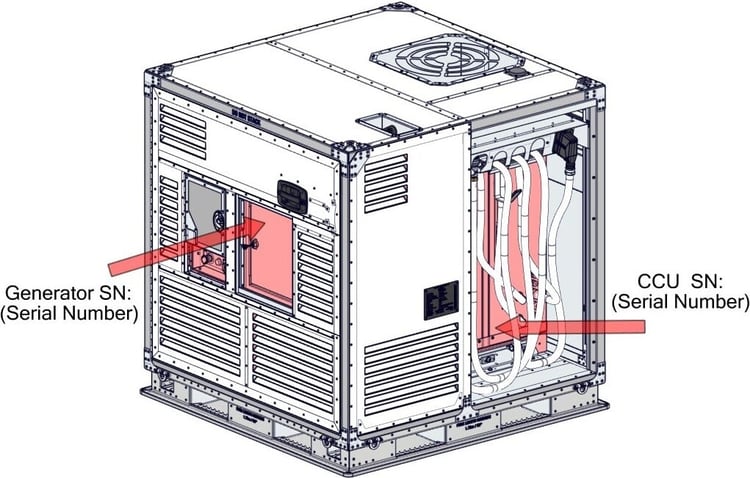

Make sure to have the manufacturing number of the Climate Control Unit is available for the support line. This can be found on the location as shown in the picture. (Inform ASML)

inform forwarder/supervisor on how and where to re-fill oil. Use the Operating Manual or generator manual for detailed instructions.

If no solution can be found, the forwarder/supervisor may consider calling E-Power for support.

When calling E-Power, make sure to have the "type" and "Nr - Year" numbers of the generator available for the support line. This can be found on the location as shown in the picture. (Inform ASML)

Consider making an appointment to a Part 145 certified repair station. (Inform ASML)

Call Emergency services

Call forwarder/supervisor (Inform ASML)